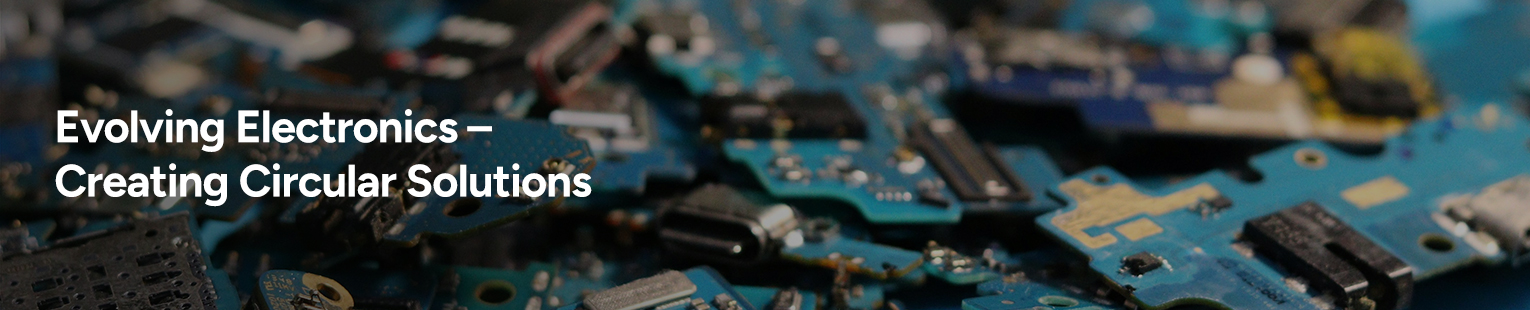

The Global Electronics Association (formerly IPC) has engaged with many industry stakeholders to explore the concept of circularity for electronics focusing on the challenges, opportunities, and actionable solutions to promote sustainable practices. We document these insights and identify the most pressing issues in the Circularity for Electronics: Proceedings Report

Below you'll find a range of additional resources that outline pathways to circularity. This page provides you with information intended to help your organization prioritize solutions so that we can work towards resolving challenges together.

We will continue to expand the inventory of resources, so please bookmark this page and be sure to check back for updates.

Closing the Loop: How Circularity Powers Sustainable Progress

Circularity aims to create systems where resources are reused, recycled, or repurposed to minimize waste and maximize efficiency. It is vital for sustainable development, reducing environmental impact, conserving resources, and creating economic opportunities. Benefits include:

- Resource Conservation: Minimizing extraction of finite materials through reuse and recycling, and other “Re” terms that promote recovery.

- Waste Reduction: Designing products for longevity and repairability.

- Energy Efficiency: Reducing energy demands in production.

- Economic Growth: Unlocking business opportunities in recycling and refurbishing.

- Environmental Protection: Lowering emissions and pollution.

Breaking Barriers to Circularity: What the Electronics Industry Must Overcome

Achieving circularity for electronics means working together to overcome key challenges, including the need for:

- Data availability: Lack of reliable, consistent (or standardized) data hinders life cycle assessments (LCAs) and informed decision-making.

- Economic incentives: Insufficient return on investment for adopting circular practices discourages investment.

- Design for circularity: Existing products are not designed for reusable or repairable disassembly nor optimized for material recovery when life extension is not feasible.

- Supply chain coordination: Fragmented supply chains struggle to align efforts for effective circularity.

- Awareness and Education: Limited understanding of circular principles among stakeholders.

A curated selection of resources

to help your organization

The below resources will help you to addressing the challenges of circularity you and many others faced when striving for sustainability goals. This section will be continuousely updated with more content as it become available.

Get involved in our standards development teams

We encourage industry involvement in IPC standards that support circularity initiatives by inviting you to participate in standards development teams, including:

- IPC-7711/21 - Rework, Modification and Repair of Electronic Assemblies (Watch Video)

- IPC-7731 - Rework, Modification and Repair of Electronic Assemblies for Wire Harness

- IPC-7712 - Component Reclaim

To join the task group for any of these standards, visit our Join a Committee page and indicate your standard of interest.

Join the conversation by completing the form as we continue our work in circularity for electronics.

The Global Electronics Association is committed to helping the industry build electronics better and we are excited to continue these efforts with our network of partners: Anthesis, Circular Electronics Partnership, EarthShift Global, imec, iNEMI, ITI, RBA, and SERI.