ICYMI: Electronics Manufacturing Is Huge in California

By Chris Mitchell, IPC vice president, global government relations

Key Summary

• California is the #1 state for electronics manufacturing in the United States.

• The state has the highest concentration of IPC members, with 98 companies across 291 sites.

• Electronics manufacturing in California spans PCB, EMS, OSAT, and major end-use sectors including aerospace, automotive, defense, and IT.

• The industry employs 275,000 people directly and supports an additional 700,000 jobs statewide.

• Key challenges include workforce shortages, global competition, and vulnerability to supply chain disruptions.

When most people think of California, they think about miles of beautiful beaches, the Pacific Ocean, wineries, national parks and cities brimming with excitement. But did you know California is the #1 state in the United States for electronics manufacturing?

That’s just one of the reasons that IPC is convening IPC APEX EXPO 2024 in Anaheim, but it’s a pretty good reason.

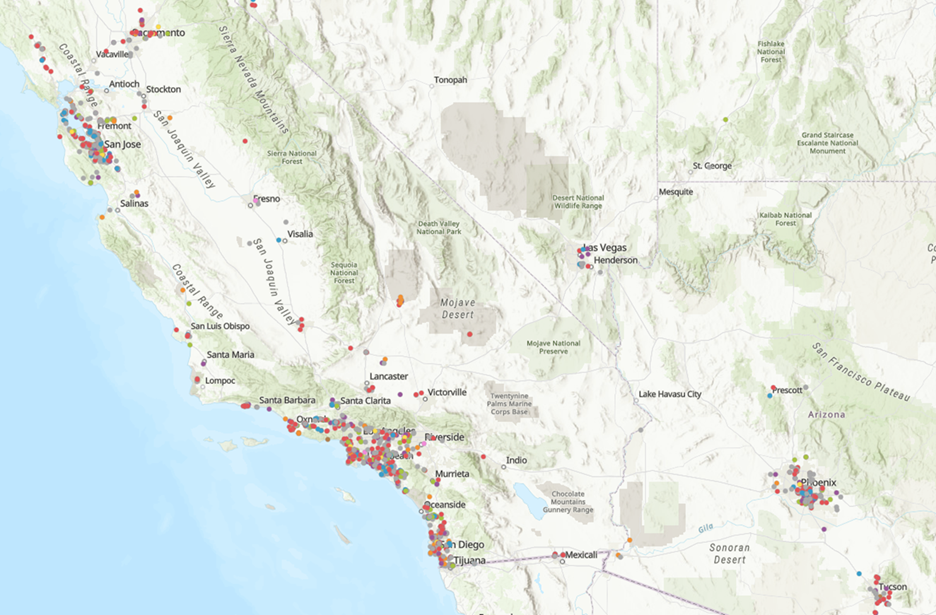

Perhaps it’s not surprising that my home state -- the nation’s largest state and the home of the integrated circuit and Silicon Valley -- is also home to the nation’s largest concentration of IPC members, 98 in all, spread across 291 sites.

California’s EM industry is well represented across all of its sub-sectors, from PCB to EMS and OSAT. It’s found in both southern California and the Bay Area; Orange County, the site of IPC APEX EXPO, has one of the highest concentrations of electronics manufacturing services (EMS) companies in North America.

Several of the world’s top companies in the field are based in California, including Flex, Green Circuits, Jabil, Sanmina, Summit Interconnect, and TTM Technologies.

And California’s electronics manufacturers are key players in several of the world’s most important end-product markets, including aerospace, automotive, defense, and information technology and communications.

Not surprisingly, the economic impacts of this industry in California are huge. According to IPC data, electronics manufacturers directly employ about 275,000 people and help support an additional 700,000 jobs in the state. Including indirect and induced output, California has over $300 billion in annual electronics manufacturing output, followed by Texas at over $110 billion.

The industry’s prominence in California means the state is also experiencing the industry’s greatest challenges:

- A shortage of skilled workers and too few defined career paths for young EM professionals.

- Stiff competition from other regions of the world that have developed equal or better ecosystems for electronics manufacturing and innovation.

- Vulnerability to global supply chain shocks such as those that occurred during and after the COVID pandemic.

Come join us in California for IPC APEX EXPO 2024. Register today!

Because it has the largest concentration of electronics manufacturing companies, the highest number of IPC members, and a long history as the home of Silicon Valley and the integrated circuit.

California’s electronics industry spans PCB manufacturing, EMS, and OSAT, with major activity in both Southern California and the Bay Area.

The industry directly employs about 275,000 people and supports roughly 700,000 additional jobs statewide.

Aerospace, automotive, defense, information technology, and communications all depend on California’s electronics ecosystem.

The industry faces a shortage of skilled workers, increasing global competition, and vulnerability to supply chain disruptions like those seen during the COVID pandemic.