Rising Material and Labor Costs Challenge Electronics Manufacturers Worldwide

New data from IPC show that high material and labor costs are expected to continue for the foreseeable future while recruiting and retaining skilled talent continues to be a challenge.

IPC’s March economic update and global electronics manufacturing supply chain sentiment reports found that more than nine in 10 manufacturers have experienced an increase in lead times for parts and components since the start of the pandemic, with approximately half indicating an increase of one to three months. The overall global economic picture is also complicated by the emerging Russia-Ukraine conflict.

Among other conclusions, the IPC survey results show:

- More than three-fourths of electronics manufacturers are currently experiencing rising material and labor costs, and most expect to see this trend continue for the next six months.

- Ease of recruitment, inventory available from suppliers, and profit margins are all declining.

- Sentiment improved slightly this month, suggesting that supply chain constraints are continuing to ease.

- Firms operating globally are seeing a quicker rate of improvement in terms of inventory available from suppliers compared to those operated only in North America.

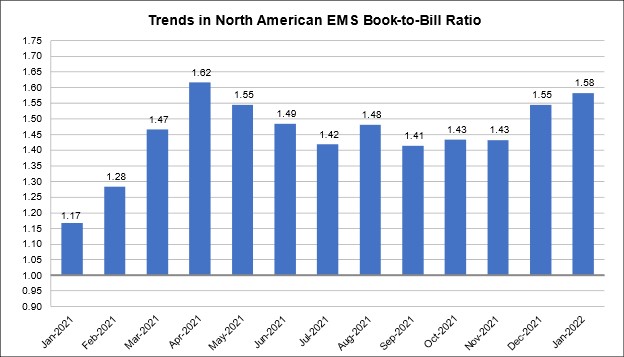

Per the economic report, the economy is holding up well in the western hemisphere. Economic activity in the first quarter could be negatively impacted by the lingering impact of the omicron variant, as it was by the delta variant in the third quarter. But because the spread of the virus is slowing, U.S. GDP growth looks positive over the coming months, advancing in the range of 3 to 4 percent, a notable increase from 1 percent in the second half of 2021. The picture is less clear in Europe, where the Russia-Ukraine conflict will have more direct impacts.

“Any disruption to an already stressed supply chain can have an outsized impact,” said Shawn DuBravac, IPC chief economist. “Until recently, there was a general feeling in Europe that the economy was set to accelerate and leave COVID in its rearview mirror. The Russia-Ukraine conflict changes this somewhat.”

IPC surveyed hundreds of companies from around the world, including a wide range of company sizes representing the full electronics manufacturing value chain.

View the full reports: