Electronics Industry Wrestles with Cost Pressures and Weaker Profitability

Electronics manufacturers are facing rising material and labor costs according to the Global Electronics Association’s June Sentiment of the Global Electronics Manufacturing Supply Chain Report. The Material Costs Index is above its long-term average and has not been this high since March 2023.

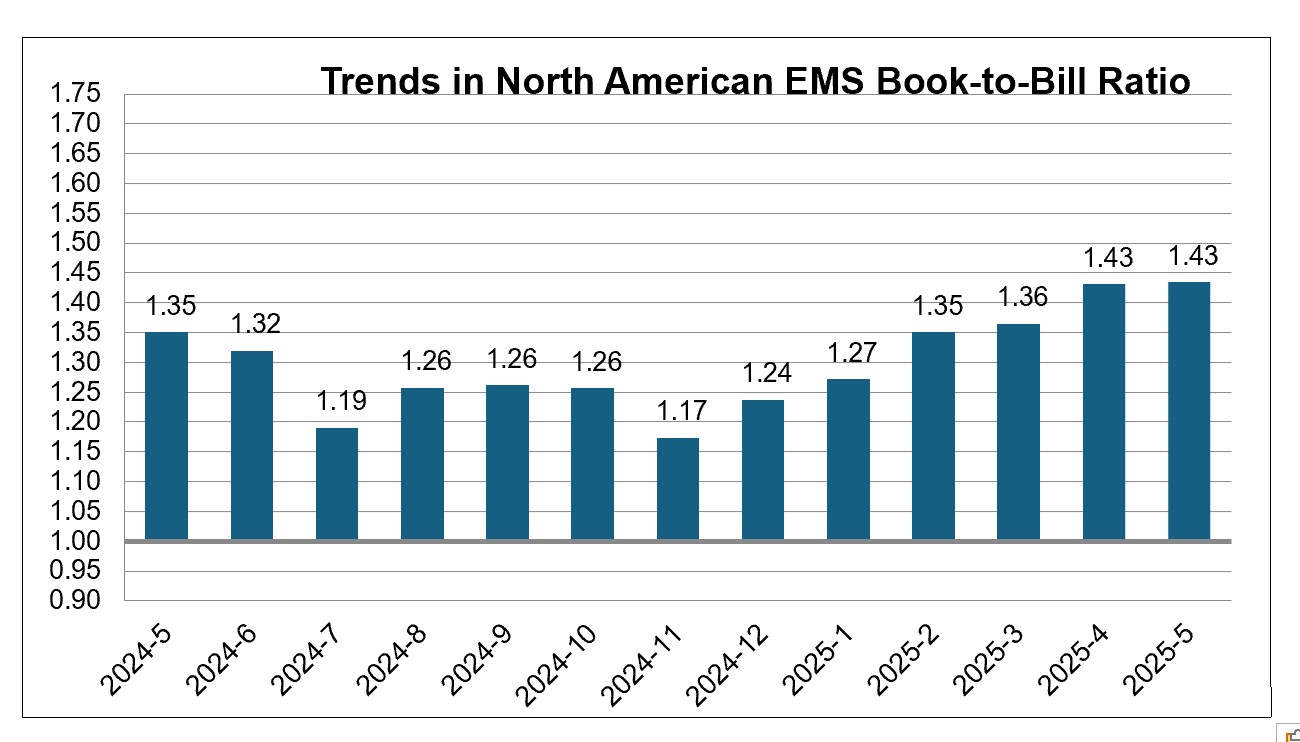

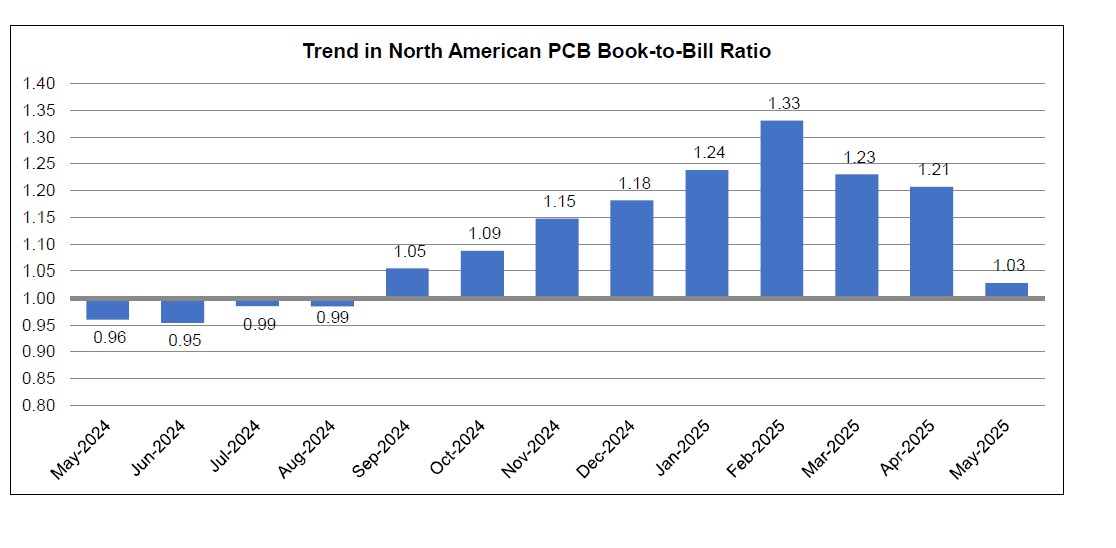

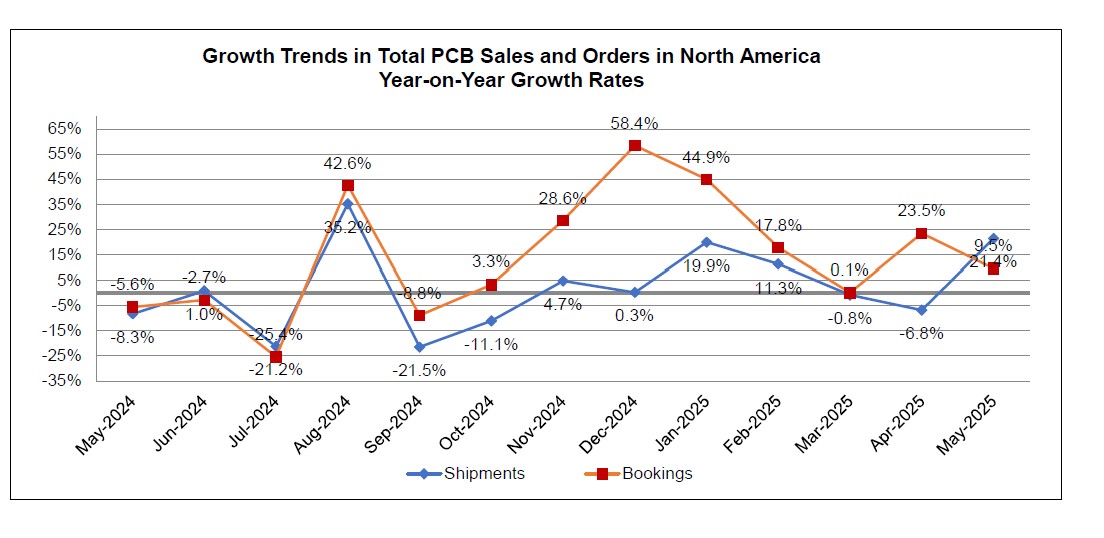

Despite market volatility, product demand shows resilience, rebounding as strongly from late-2024 lows. Orders, backlogs, capacity utilization and shipments are each strongly in expansion territory.

Over the next six months, electronics manufacturers expect material and labor costs to remain high, while ease of recruitment is expected to remain challenging. Demand, however, will remain intact. Manufacturers anticipate relative stability in orders, backlogs, shipments and capacity utilization, suggesting slow but steady operations amid headwinds.

Shawn DuBravac, Ph.D., Global Electronics Association’s chief economist and report author noted, “Bottom line, as the electronics manufacturing supply chain enters the second half of 2025, it will confront stubborn input inflation, but a solid demand outlook. Tight margins, persistent hiring challenges, and targeted capacity shifts will keep cost control and operational agility at the center of decision‑making throughout the remainder of the year.”

Additional survey data show:

- Global manufacturers, along with those in North America, are more likely to expect a decline in profit margins compared to firms in Europe and APAC.

- Supplier inventory is rising more for electronics manufacturers in APAC than those in North America, Europe, and among those operating globally (multiple countries).

- Over the next six months, orders are expected to decline more for firms operating globally than for those in Europe.

These results are based upon the findings of the Global Electronics Association’s Current State of Electronics Manufacturing Survey, fielded between May 14 and May 31, 2025.

Read the full report.