Amsterdam Sets the Stage for Sustainability: Highlights from Sustainability Week Europe 2025

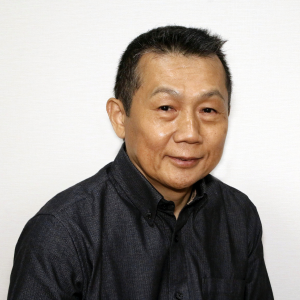

By Diana Radovan, Sustainability Policy Director, Global Electronics Association

Key Summary

• Sustainability Week Europe 2025 highlighted shared challenges across diverse sectors, emphasizing collaboration over polarization.

• Speakers stressed that circularity succeeds only when supported by systems thinking, scalable processes, and clearer business-focused terminology.

• A major theme was reframing sustainability as a business proposition, not just a moral one, especially amid regulatory complexity and competitiveness pressures.

• Participants called for smarter, more practical regulations and stronger alignment between sustainability goals and business outcomes.

• The event underscored the urgency of action to support Europe’s digital and green transition.

Diverse sectors came together in Amsterdam on Oct 6-7 to discuss hot topics around sustainability, at the intersection of regulation, strategy, and competitiveness. Despite the diversity of industries and stakeholders present in the room (AI startups, investors, electronics, clean energy, fashion, pharmaceuticals, philanthropies, etc.), sustainability challenges and opportunities shared a similar vocabulary, and it was easy to find common ground and learn from each other’s experiences. Following the interesting roundtable discussions at the Chief Sustainability Officers (CSO) club on Monday, October 6, plenary panels, interviews, and networking sessions took place the next day, including a talk by and a conversation with the Mayor of Amsterdam, Femke Halsema.

My key takeaways from the event can be grouped into three main areas:

Focus on collaboration and real impact

We cannot afford to quarrel over symbolic issues, we need to be pragmatic, by addressing the things that really matter, and avoid polarised speech. We have to work together in Europe and internationally

Circularity strategy and terminology

Circularity works if appropriate systems are put in place from the very beginning. In this context, systems thinking is key. Circularity fails in a linear world. Efficiency and scale up are possible if approached with a sustainability mindset. More secondary raw materials are necessary in the products we are building. In addition, those of us who are sustainability professionals may need to refine our terminology when pitching our circularity business case to CEOs, because ‘circularity’ does not necessarily sound like business growth: circularity can be seen and framed as an important business opportunity, involving less waste and less resources.

Sustainability as a business proposition

Nowadays, in light of competitiveness challenges and geopolitical movements, sustainability professionals need to build a business case, not only a moral case, in their organizations, in order to be effective in their efforts. Many participants were of the opinion that smart regulations can be an opportunity for businesses to measure risks and build a better business. Nonetheless, sustainability isn’t always driven by regulation and sustainability regulations don’t always mean more sustainability, sometimes they just mean more reporting. Sustainability regulations often remain, however, impractical and fragmented, and more needs to be done on the path towards their improvement, which is what we, at the Global Electronics Association, continue to advocate for.

Panelists and participants may have had, at times, different perspectives in their approach to sustainability and reaching sustainability goals, but ultimately, what I heard at this event was a very pragmatic call-to-action, and moving away from older, idealistic views on sustainability. We cannot be sustainable and support the digital and green transition if we ignore the high regulatory reporting burden and the acute need to link sustainability efforts to business outcomes.

We need to act now, not later.

To learn more about the event, contact me at DianaRadovan@electronics.org.

The event focused on pragmatic sustainability—collaboration, impact-driven strategies, and aligning environmental goals with real business outcomes.

Panelists emphasized that circularity only works when supported by systems thinking, early design planning, and scalable infrastructure, enabling companies to reduce waste and resource use.

Leaders stressed the need to present sustainability as a business opportunity by linking it to competitiveness, risk management, efficiency, and long-term value creation.

Many regulations are fragmented or overly focused on reporting, making them difficult to implement; participants called for smarter, more practical policy design.

A clear call to act now—companies must move beyond idealistic concepts and integrate sustainability into business strategy to support Europe’s green and digital transition.